Dec 01, 2016

I have an ABC analysis. Now what?

In our previous blog posts, we looked why you should classify your products into ABC and how exactly to do that. So now that you’ve learned more about the benefits of classification, the next logical question is “What do I do with it?”

It is important to know which items are your bread-and-butter items, and which ones should be considered for not stocking at all. But there’s so much more you can do with this incredibly powerful tool. In this post, we’ll look at how to get the most out of your classification matrix.

If you have a good replenishment or planning app, it will always show you where in the matrix your item falls. This is important information that you should always think about when dealing with an item, and it should be easy to access. For example:

When dealing with excess inventory

When an item is flagged as being in excess, pay attention to its velocity. If the item is a High Velocity item, don’t worry too much about excess – it will sell soon enough. Just keep your next order a little smaller to get the levels back on track.

However, if it’s a Low Velocity item, this is a big red flag: You have too much and it sells very slowly. You have to kick into action to get rid of the excess of these items. You may want to have a mark-down sale or even send the product back to the supplier. Whatever you do, you’ll want to get rid of that inventory. And be very careful when ordering more. You don’t want to spend all that energy getting rid of excess, then go and reorder more!

When dealing with Surplus Orders

Again, a very similar principle applies here. If you’ve ordered some surpus of items that move quickly, that’s not the end of the world. But ordering too much of slow moving items is a cardinal sin. And you’ll have to kick into fire-fighting mode immediately. You should cancel — or at least delay — the order.

The only rider on this is to look at the Cost Price of High Velocity items that are over-ordered. If they have a high cost (including AH) items, you may want to cancel the order, for the sake of better cash flow in your business.

When dealing with stocked-out items

Your first priority with stocked-out items is to deal with the High Velocity items, especially the AH items. Every day you are out of stock of an AH item, you’re bleeding cash flow. You have to straighten this out immediately! It may be better for your business to buy from a non-preferred supplier with a higher cost than to run out of AH items.

On the other hand, if you’re stocked out of Low Velocity items, you shouldn’t make these your first priority – especially if it’s a CL item. This may even be a good time to see if your business will suffer from not stocking those CL items at all. Often, there won’t be any adverse results from that.

Set stocking policy by classification

It’s useful to know an item’s classification when dealing with exceptions, as well as when you’re setting Stocking Policy.

Obviously, you never want to reorder Obsolete items, and you only ever want to order Non-stocked items when there’s firm demand, like a Customer Order for the item.

But what about the rest? Let’s take a look.

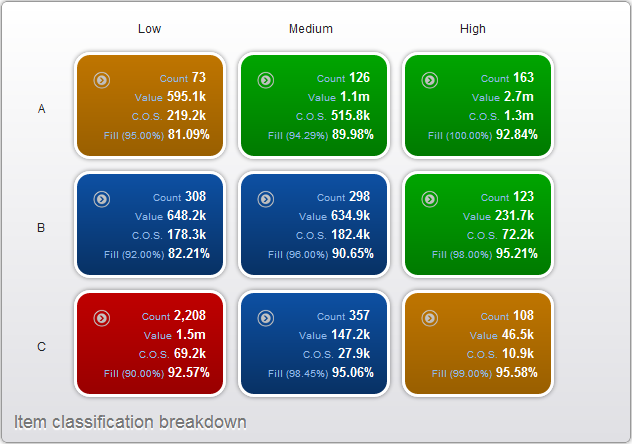

Inventory ABC Classification Matrix that includes HML Classification

The green blocks

These are your most important items. You want to set a high target Fill Rate on these items. The way that Safety Stock increases exponentially with higher fill rates makes impossible to target 100% – as you would have to keep an infinite amount of inventory – but you can go pretty high. You should aim for at least 97%.

Typically, you would also want to reduce your Replenishment Cycle for these items. This means that you order these items more frequently, forcing you to review these items regularly. Also remember that the shorter you make the Replenishment Cycle, the higher your Safety Stock goes – the more orders you have “in-flight”, the higher the risk that something can go wrong, and you stock out.

The red block

This is the polar-opposite of the green blocks. There is both a low demand and a low margin on these items. You can really afford to target a much lower Fill Rate on these items because it doesn’t matter that much if you run out of stock. Target something low like 90%.

You don’t want to be bothered with these low-margin items, so be sure to set a long Replenishment Cycle. Something like 90 days will work well. This allows you to just buy a big quantity of these slow movers every 90 days, and forget about them.

The first brown block

These A-Low items are your slow-moving, high-margin products. Because they are expensive, you probably cannot go for a very high Target Fill rate. In fact, you can probably target 90% here too. These are often items that your customers will wait for, even if you run out.

You don’t want to review these slow movers too often, but you also don’t want to “set-and-forget” them either. So a Replenishment Cycle somewhere in-between it probably good. Something like 45 days should suit your need.

The other brown block

Those are the C-High items. They’re inexpensive, but move fast. Go for a higher Target Fill Rate than the other brown block. Say 93% or so.

You can also get away with just ordering bigger batches of these at a time. After all, they’re inexpensive and you don’t want to spend every day worrying about these items. Go for something like a 60 days Replenishment Cycle. That should keep them out of your hair, but still keep the sales ticking over.

The blue blocks

You may have to experiment with these “middle-of-the-road” items. But a good rule of thumb would be to just target a lower Fill Rate like 92% and review them every 30 days.

Setting your policy by the matrix gives you two advantages

First, you will invest your working capital where it will have the biggest impact on your business.

Second, you will employ your valuable time and attention on the items that really matters to your business

In the next blog post in this series, we will go into the benefits in more detail. So be sure to check back, and until then, happy classifying!

Classifying inventory was a laborious process for US - based Aurora Lighting until they discovered NETSTOCK. Download their case study here to get insights into their inventory journey.

Written by Barry Kukkuk

In 2010 Barry began his journey with NETSTOCK. His enthusiasm for Inventory Management and his strong belief in “all things Cloud” collided resulting in the release of the Inventory Management solution - NETSTOCK. Barry is the CTO at NETSTOCK, where he is responsible for all customer-facing technologies and systems that keep thousands of NETSTOCK customer instances working correctly.